Unleashing the Power of 3D Printing Solutions

- innovative3dprint

- Oct 20, 2025

- 4 min read

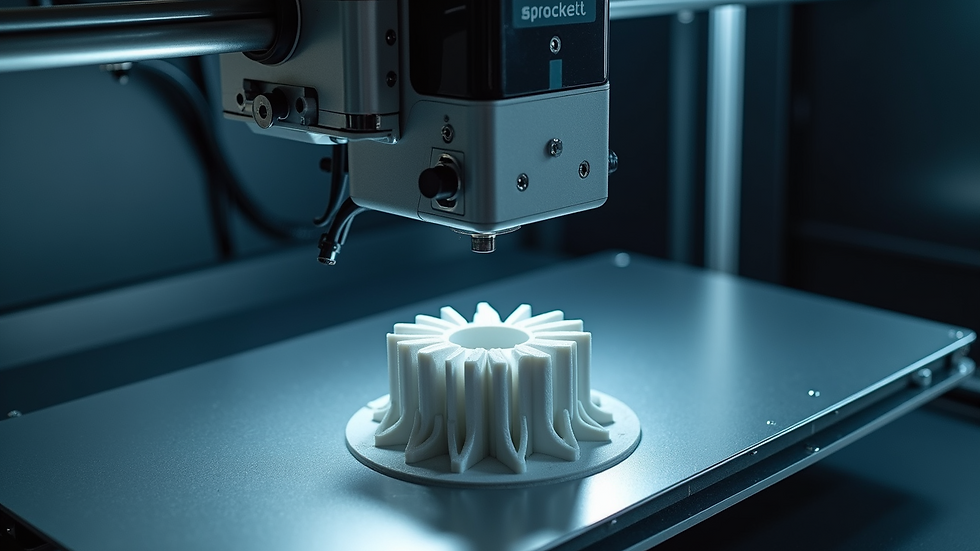

Imagine a world where you can create almost anything you dream of, right from your computer to a physical object in your hands. That’s the magic of 3D printing. But how do we truly unlock its potential? How can we use custom 3D printing approaches to transform ideas into reality efficiently and effectively? Let’s dive into this exciting technology and explore how it can revolutionize the way we create.

Why Custom 3D Printing Approaches Matter

Have you ever thought about why customization is so important in 3D printing? Unlike traditional manufacturing, 3D printing allows us to tailor every detail of a product. This means no more one-size-fits-all solutions. Instead, we get parts and products designed specifically for unique needs.

Custom 3D printing approaches give us the flexibility to:

Create complex geometries that are impossible with conventional methods.

Reduce waste by using only the material needed.

Speed up prototyping and product development.

Produce small batches cost-effectively.

Personalize products for individual preferences or specific applications.

For example, a business needing a specialized machine part can get it printed exactly to specification without waiting weeks for traditional manufacturing. Or an individual can order a custom-fit accessory that matches their style perfectly.

Exploring Different Custom 3D Printing Approaches

So, what are the main custom 3D printing approaches we can use? Let’s break down some popular methods and how they serve different purposes.

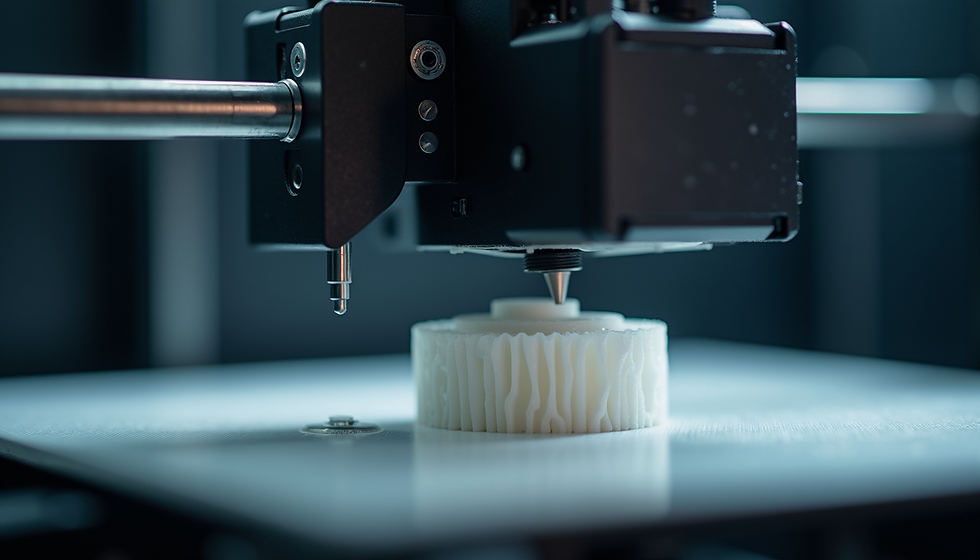

Fused Deposition Modelling (FDM)

FDM is one of the most common and affordable 3D printing techniques. It works by melting plastic filament and layering it to build the object. This approach is great for:

Functional prototypes

Durable parts

Low-cost production runs

Stereolithography (SLA)

SLA uses a laser to cure liquid resin into solid layers. It produces high-resolution, smooth parts ideal for:

Detailed models

Jewelry and dental applications

Visual prototypes

Selective Laser Sintering (SLS)

SLS fuses powdered materials with a laser, creating strong, complex parts without support structures. It’s perfect for:

Functional end-use parts

Complex geometries

Small to medium production runs

Each approach has its strengths, and choosing the right one depends on your project’s requirements. The beauty of custom 3D printing is that we can mix and match these methods to get the best results.

What is the 45 Degree Rule for 3D Printing?

Have you heard about the 45 degree rule? It’s a simple but crucial guideline in 3D printing that helps ensure quality prints without excessive support material.

The rule states that any overhang in your design should not exceed 45 degrees from the vertical. Why? Because angles steeper than this tend to sag or fail during printing without support.

Here’s why it matters:

Reduces the need for supports, saving material and post-processing time.

Improves surface finish by avoiding marks left by support removal.

Speeds up printing by simplifying the build.

When designing custom parts, keeping the 45 degree rule in mind helps us create more efficient and cleaner prints. If your design requires steeper angles, consider adding supports or redesigning the geometry.

How to Maximize the Benefits of 3D Printing Solutions

Now that we understand the basics, how do we make the most of 3D printing? Here are some practical tips to unleash its full power:

Start with a clear design goal. Know exactly what you want to achieve before printing.

Choose the right material. Different materials offer various strengths, flexibility, and finishes.

Optimize your design for printing. Use software tools to check for errors and apply rules like the 45 degree guideline.

Test with prototypes. Print small versions to check fit and function before full production.

Work with experienced providers. Partnering with experts ensures quality and technical support.

By following these steps, we can avoid common pitfalls and deliver parts that meet or exceed expectations.

If you want to explore professional 3d printing solutions tailored to your needs, working with a trusted service provider is key. They can guide you through material choices, design optimization, and finishing options.

Taking Action: How to Get Started with Custom 3D Printing

Ready to bring your ideas to life? Getting started with custom 3D printing is easier than you think. Here’s a simple roadmap:

Define your project scope. What part or product do you need? What are the size, strength, and finish requirements?

Create or source a 3D model. Use CAD software or hire a designer to develop your digital file.

Select a printing method and material. Match your needs with the best technology and material.

Find a reliable 3D printing service. Look for providers with experience, good reviews, and technical support.

Review prototypes and iterate. Don’t hesitate to tweak your design based on test prints.

Place your final order. Once satisfied, produce your parts in the desired quantity.

By following this process, you’ll save time, reduce costs, and get exactly what you need.

Embracing the Future with Custom 3D Printing

The possibilities with custom 3D printing approaches are endless. From rapid prototyping to producing final parts, this technology is reshaping manufacturing and design. It empowers us to innovate faster, reduce waste, and personalize products like never before.

Are you ready to unleash the power of 3D printing? Let’s take the first step together. Explore your options, experiment with designs, and partner with experts who can turn your vision into reality. The future of manufacturing is here, and it’s custom, creative, and incredibly exciting.

Start your journey today and see how custom 3D printing can transform your projects and business.

Comments