Accelerate Innovation with Rapid Prototyping

- innovative3dprint

- Aug 7, 2025

- 3 min read

When we think about bringing new ideas to life, speed and accuracy are everything. How often have we wished for a way to test our concepts quickly, without waiting weeks or months? That’s where the benefits of rapid prototyping come into play. It’s a game-changer for anyone needing custom parts or innovative designs. Let’s dive into how this process can transform your projects and help you stay ahead.

Why the Benefits of Rapid Prototyping Matter

Have you ever had a brilliant idea but struggled to see it in physical form fast enough? The benefits of rapid prototyping mean you don’t have to wait. This process lets us create models or parts quickly, test them, and make improvements on the fly. It’s like having a fast-forward button for innovation.

Here’s why it’s so valuable:

Speed: Instead of waiting weeks, you get a prototype in days or even hours.

Cost-Effective: Early testing reduces costly mistakes later.

Flexibility: Easily tweak designs based on real-world feedback.

Better Communication: Physical models help everyone understand the concept clearly.

Risk Reduction: Spot potential issues before full production.

Imagine you’re developing a new gadget. With rapid prototyping, you can hold a working model in your hands quickly. You can test how it fits, feels, and functions. Then, you adjust the design and test again. This cycle speeds up innovation and ensures the final product is exactly what you want.

How to Use Rapid Prototyping to Boost Your Projects

So, how do we make the most of this powerful tool? First, start with a clear design. Use CAD software to create your model. Then, choose the right prototyping method based on your needs. Some common techniques include:

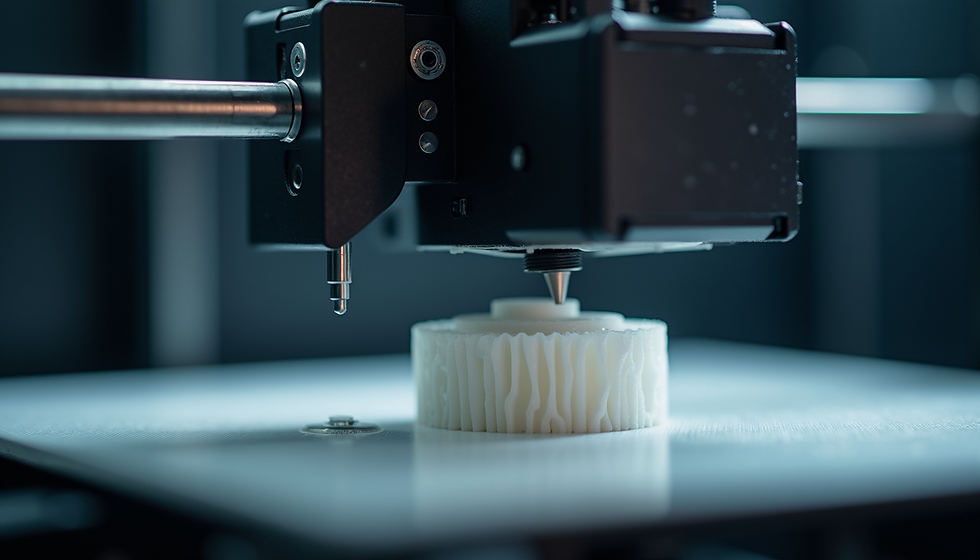

3D Printing - Great for complex shapes and quick turnaround.

CNC Machining - Ideal for strong, precise parts.

Injection Moulding - Useful for testing production-ready parts in small batches.

Once you have your prototype, test it thoroughly. Check for fit, function, and durability. Gather feedback from your team or clients. Then, refine your design and repeat the process. This iterative approach saves time and money by catching problems early.

Don’t forget to work with a reliable partner who understands your goals. For example, rapid prototyping services from Innovative3D offer expert support and high-quality results. They can help you choose the best materials and methods for your project.

Is rapid prototyping the same as 3D printing?

This is a question we hear a lot. The short answer? Not exactly. 3D printing is one method of rapid prototyping, but rapid prototyping covers a broader range of techniques.

3D printing builds parts layer by layer from digital files. It’s fantastic for creating complex shapes quickly and cost-effectively. However, rapid prototyping also includes other methods like CNC machining, vacuum casting, and injection moulding. These can be better for certain materials or production volumes.

Think of 3D printing as a powerful tool in the rapid prototyping toolbox. Depending on your project, you might use one or several methods to get the best results. The key is to choose the right approach for your specific needs.

Practical Tips to Maximise the Benefits of Rapid Prototyping

Ready to get started? Here are some actionable tips to help you accelerate innovation with rapid prototyping:

Start Simple: Begin with basic models to test core ideas before adding complexity.

Iterate Quickly: Don’t wait for perfection. Test, learn, and improve fast.

Use the Right Materials: Match prototype materials to the final product’s requirements.

Collaborate Closely: Keep communication open between designers, engineers, and manufacturers.

Document Changes: Track every iteration to understand what works and why.

Plan for Testing: Set clear goals for each prototype to measure success.

By following these steps, you’ll reduce development time and increase your chances of success. Remember, the goal is to learn and improve, not just to create a perfect first version.

Taking the Next Step with Rapid Prototyping

Are you ready to bring your ideas to life faster and smarter? The benefits of rapid prototyping are clear. It’s a proven way to reduce risk, save money, and innovate with confidence. Whether you’re creating custom parts or testing new designs, this approach puts you in control.

Don’t wait months to see your ideas in action. Start exploring rapid prototyping today. Reach out to experts who can guide you through the process and deliver high-quality results. With the right partner, you’ll accelerate your innovation and turn concepts into reality faster than ever.

Let’s make your next project a success. Take action now and discover how rapid prototyping can transform your workflow and outcomes.

Ready to speed up your innovation? Contact Innovative3D to learn more about their expert rapid prototyping services and start creating your custom parts today!

Comments